Vegetable dyes textile printing cotton and silk fabrics

In june and July 1989, I learnt vegetable dyes textile dyeing and printing, as a intern, at the Weavers service Center, Hyderabad, Telangana (then Andhra Pradesh) India. The Weavers service Center, welcomed me in the very lively city center of Hyderabad, one of the twin cities ( the other one being Secunderabad). Gandhi created these craft studios dedicated to research and weaving, printing, manufacturing, in order to promote local and traditional textile skills from each region of India, and to cooperate with local textile companies, redesigning ancestral motives and their natural shades.

KalamKari, ikat weaving, block printed fabrics, rich golden embroideries are famous in Hyderabad aera. Many years of partnership with local craftsmen and design studios followed this two months training. Most of my collections were created thanks to them.

Here are a few extracts of the dyeing and printing secrets given by craftsmen, at the Hyderabad Weavers service center, during the summer 1989. I started the training with a designer and flat pattern-maker background, and it wasn’t necessary to have any knowledge in chemistry before starting it. Don’t try them out at home, but the weavers service center should be accepting visits and provide further informations on workshops.

The craftsmen were incredibly skilled. The delightful fabrics of cotton and silk, displayed at the Center’s show-room, marked the amazing start of two months apprenticeship.

Block printing

Here is how it started with vegetable dyes textile printing.

How to use vegetable dyes for textile printing on cotton silk fabrics ?

Boil the cloth in water in order to remove the starch and then dry it. Boil it again for 20 minutes in 6 liters of water, along with myrobolam (10 to 15% of the cloth). Then dry the cloth for 2 or 3 days.

Fix the cloth with the help of pins on a long table, whitout ironing it previously. Protect the table with a few layers of cloth. First prepare the color, following the below recipes. The printing process starts with the background color.

Use a wooden small size tub for the color in which an oiled cloth is first layered, then a jute cloth and a piece of light and airy cotton on top.Pour the color into the tub until evenly filled up using a spatula.

Apply the block print 2 or 3 times onto the color, thoroughly, and then put it on a piece of newspaper, and finally on the cloth. Heat 2 or 3 times the block, so that it prints properly the cotton. It is advisable to draw a straight line directly onto the cotton, to have straight design printing. For each color there is a different block, and as many block printing process repeated as the n°of colors.

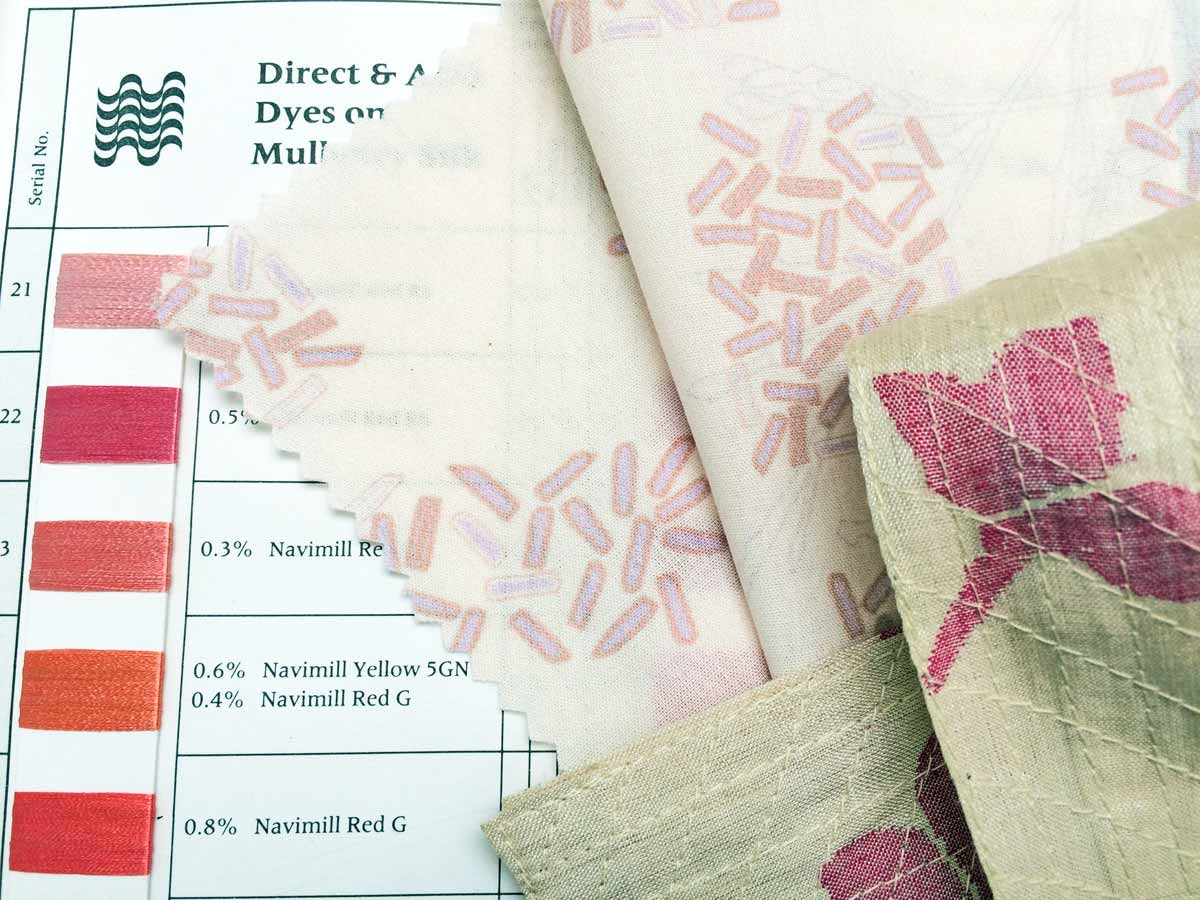

Vegetable dyes textile printing: The colors used for printing

Red color

For 30g of arabic gum, 30g of alum, 1/2 litter of water. Stir it for 15 min. The result is a thick substance. As per the % of alum, the final color is more or less bright or light red.

Indigo blue

1 litter of water for 70g of starch powder

25g of indigo blue

12,5 g of caustic soda

25 g Hydros

Procedure:

Add the 70g of starch powder to the liter of water, and stir well. Then add caustic soda and stir well. Mix Indigo blue in a separate bowl with water. After mixing it well, then add into the paste. Add Hydros. It should have a greenish tone, and if it has a bluish tone, then add more hydros to the paste. Instead of hydros, we may use Ranjoline C20Y, the results are better compare with hydros.

Dry the cloth under the sun light , wash it and dry it again for 2 or 3 hours.

To block print with indigo blue, the wooden tool has to passed very often into the wooden tub, to avoid the indigo changes in the contact of the oxygen. Add often indigo blue color the the wooden tub.

Turn the jute cloth in the tub, distribute the color with the tool and wash often the block with a brush.

Black color

20 g of arabic gum and 15 g of alum for 1/2 liter of water. Stir it for 10 or 15 min.

1 kg of iron scrap

1/2 Kg of palm jiggly (unrefined brown sugar).

5 liters of water

The mixture is allowed to ferment for 21 days in an earthen jar, not in a plastic jar. After 21 days remove the iron scrap, add 200 g arabic gum and stir for 10 or 15 min. If the iron scrap is new, then burn it first, and keep it soaked in water for 1/2 an hour.

Then splash it with water until the iron rusts.

Maroon color

10% of alum, 15 g of arabic gum, 8% of cloth weight black color, 1/2 liter of water.

Stir for 15 min the water and the arabic gum, then add the alum. Then the black color, stir for 10 min.

As per the result wished, the black color and the alum are more or less added.

Brown

20% of alum, 10% of cloth weight black color, 1/2 liter of water, 15 g of arabic gum.

Myrobolam: yellow color, floral origin

Put the Myrobolam flowers in a stone mortar, then crush them into powder. They are then put in 2 liters of boiling water. 1/2 liter of water evaporates, then add the alum along with the arabic gum, stir it each 5 min.

150 g of myrobolam powder + 1/2 liter of water.

10 g of alum, 15 g arabic gum . Mix it all for 15 min in a tumbler.

Put the cloth into boiling water, to remove the starch, and then dry it. Then soak the cloth along with the myrobolam powder, for 20 min in boiling water. Dry the cloth on the sun and grass, for 2 or 3 days.

For the dyeing of a light fabric, put 10% of the cloth weight of myrobolam powder, for a heavier fabric, put 15% of the cloth weight of myrobolam powder.

It is possible to add the yellow color after the development, since it would overflow the pattern design. It is the same for indigo. If a green shade is needed, it should be decided earlier. All the other colors can be mixed.

Vegetable dyes textile printing: Color’s development

The development is a process done after printing, to make the colors appear, since after the printing the colors are dull.

Process

Wash the cloth, then make water boil in an inox basin, along with jag leaves (lime tree leaves), 200 mg per ltr of water and 1 g of alizarin red.

Stir the cloth in the basin for 1/2 an hour. The colors appear little by little. The cloth is then rinsed abundantly, and stroked on the ground a few times.

The cloth can also undergo different process, in order to get different final shades:

For instance, a 3 meters cloth is dried for 2 days and then cut into 3 pieces:

The 1st piece is soaked into a basin with 3 litters of water and crushed twigs. The result is a red-pinkish background.

The 2nd is soaked into a basin with 5 litters of water and pomegranate powder. One liter of water is boiled with the cloth and pomegranate, the remaining 4 liters of water are added afterwards. The result is a maroon-pinkish background.

The third piece is soaked into a basin with one ltr of water and and bark. The result is a yellowish background with pale colors.

Each piece is soaked in water for 1/2 an hour.

Vegetable dyes textile printing : cotton and silk dyeing

Cloth preparation for dyeing :

Weight the cloth.

In this case, 10 meters= 1400 g

2% of caustic soda

Same % of soap

2% soda ash

Heat the water, add into it the soap, the caustic soda and the soda ash. Heat for 4 hours. This mixture is necessary for all the fabrics dyed with chemical colors. Then abundantly rinse the cloth. Leave it for 3 or 4 hours. Then bleach the cloth , with 15% of the cloth weight of bleaching powder. The process lasts for 45 min. Then wash the cloth and treat it with Hydrochloric acid.

Background dyeing, cotton fabric

In this case, the background color is yellow.

24 g of castor oil is mixed to 4 g of yellow die and 4 g of orange die, in a tumbler. Stir it with a glass baguette.

Then add 3 g of caustic soda per liter of water, therefore for this example 36 g for 12 liters of water. Hydros: 3 g / ltr of water, therefore 36 g for 12 liters of water. The dyeing T° is 50°. The cooking time is of 30 to 45 min.

In the basin which contains the water, the caustic soda and hydros, add the color mixture, the cloth, mix it well so that the color is evenly spread onto the cloth. Then leave the cloth in the basin, maintaining it at its bottom for the remaining time.

Pour only half of the color at the beginning, then the balance once the color well mixed to the cloth. After 45 min, put on the heat again if the T° has gone down in between the process.

Then dry the cloth for 5 min. The cloth can have dyeing irregularities, due to the movements of the cloth in the bath. Then abundantly rinse it. Then go on with the last operation: soak the cloth in a bath for 15 min: mix it with 12 liters of water, 2 g of soda ash, 2 g of castor oil, and heat it to 90°. Rinse the cloth again, and dry it. The fabric is ready.

Caustic soda opens the cloth’s fibers, and hydro fix it.

Another recipe

Mix 24 g of castor oil to 4 g of yellow die and 4 g of orange die, in a tumbler. Stir it with a glass baguette.

Put water in a basin, proportion : 1 part of fabric for 20 of water.

Add the color into the basin, and the cloth. Dye it for 30 min on the heat. Remove the cloth from the bath, press it, and soak it into cold water. Wait for the oxidation, and dry it for 10 min. Put it again in hot water with soap, during 5 min, then rinse it again in cold water.

To make the castor oil

5 kg of castor oil

10 liters of water

250 ml sulphuric acid

500g soda ash

300 g causitc ash

Pour all these ingredients in a metal or wood jar, and leave it for 5 days. Mix it once per day.

Vegetable dyes textile printing : Silk dyeing

How to use vegetable dyes for textile dyeing on silk fabrics ?

Background color

Pour the color in a tumbler, mix it with cool water. Then add boiling water.

In a boiling water’s basin, put the cloth and the color, and mix it all. For a brighter color, add caustic soda. The bath should last for 10 to 15 min. Then rinse it and drie it.

Patterns

2 liters of water for 1 kg of arabic gum. In this case, 1/4 Kg arabic gum for 500ml of water. 4 tea spoon of acetic acid and 8 g of cooking salt. Mix it for 10 min.

24 g of dye, 12 g of ether of glycol, water heated at 60°: 40 cl, 8 g of sulfate of ammonium.

The solution obtained should be 400 g; however the weight of these ingredients is 96 g. so add 304 g of arabic gum.

Put the color in a tumbler, mix it with the ether of glycol, then add the water 60°. Mix it and boil it all. To get the 304 g of arabic gum, put the tumbler containing the color in a balance, then add the arabic gum, until getting the wished weight.

Take the 8 g of sulfate ammonium, mix it to a little of water, then add it to the tumbler.

To fix the color on the silk, after the deying and printing process, give a steam bath to the cloth :

Roll up the silk in a newspaper, the cloth should be completely covered. Tie it with a thread. Then boil water in a basin, put in a wooden stand, then put a piece of plastic on the stand. Then put the roll of silk on the stand, cover the basin, keeping small pieces of wood

between the basin and its lid, to allow the air to pass. The steaming process lasts for 30 to 45 min.

Indigo dyeing

8 pounds of indigo

6 pounds of ashes

3 or 4 ounces of madder

Prior to silk indigo dyeing, clean the silk with 30 to 40% of its weight with soap, then rinse thoroughly. Don’t add any alum.

Boil the ashes and the madder for 15 min in a copper basin. Soak for 3 days 8 pounds of indigo, with hot water. Change the water in the meantime. The water gets maroon color. Then add the first solution into this bath. Ground the indigo with this in the basin, and leave it for sometimes.

Filter the mixture which has become clear, pour it in a basin, and repeat the operation until the indigo is completely grounded. Then mix well again the new mixture in the basin.

With the help of a baguette, mix it and keep it on fire. The heat must be bearable on the hand. Keep mixing, the color must become green (soak a little piece of white silk. Then you can see a fine cream brown or copper shade on the surface). Leave it for 3 or 4 hours.

Then put water in a different cauldron, boil it with to 2 pounds of ashes and 4 ounces of madder. Pour this new bath into the previous cauldron. The dye is then ready.

Put the silk on a wooden stick, and soak it into the color cauldron. Turn the stick, so that the color can penetrate all the parts of the silk, to enable you to obtain the blue shade. Then squeeze it on the cauldron, very strongly; Put it in the air, and wash many times in water. Squeeze it again, twelve times. Then dry the cloth as quick as possible.

Vegetable dyes textile printing – Studios names

A few names of the Hyderabad scene in thoses years, the 2 first ones are still ongoing there work:

Tutu’s Taneja and family, Banjara Hills-Hyderabad, made a baroque interpretation of women’s Indian apparel and stoles, which cotton are still block printed, with motives embroidered with silver threads. Their little show-room is a real Aladdin’s cave. The fabrics lay on the grass in front of the family’s houses, drying on the sun.

Creative bee designs and manufactures beautiful hand woven silk and cotton fabrics, yarn dyed with natural colored stoles or block printing cottons. Mrs Bina Rao manages brilliantly its company, and her husband, Mr Rao is an expert in textiles, dyeing, and printing.

Mrs Meera Mehra from Shafali fabrics, is a known home textiles and apparel Design Studio for more than 30 years. The ex Nizam’s house is hosting the stitching unit. This amazing house is sheltered in carved natural stones and it looks like a succession of caves. The design studio and dyeing/printing workshops are surrounded by nature. Uncountable wooden blocks with hundreds of different designs make her studio a daydream. The Indian Artist Laxma Goud has designed some of the textile prints.